Description of the service / company

Company description

G. Stadler Metallbearbeitungs-GmbH is a family business that can look back on more than 60 years of company history.

Originally founded as a farrier and wagon smithy, the company has constantly evolved and over the years has matured into a state-of-the-art manufacturing site in the fields of machining and steel construction.

The conversion or new construction of the production facility, the acquisition of new technologies and the certification according to ISO 9001:2015 were considered key milestones.

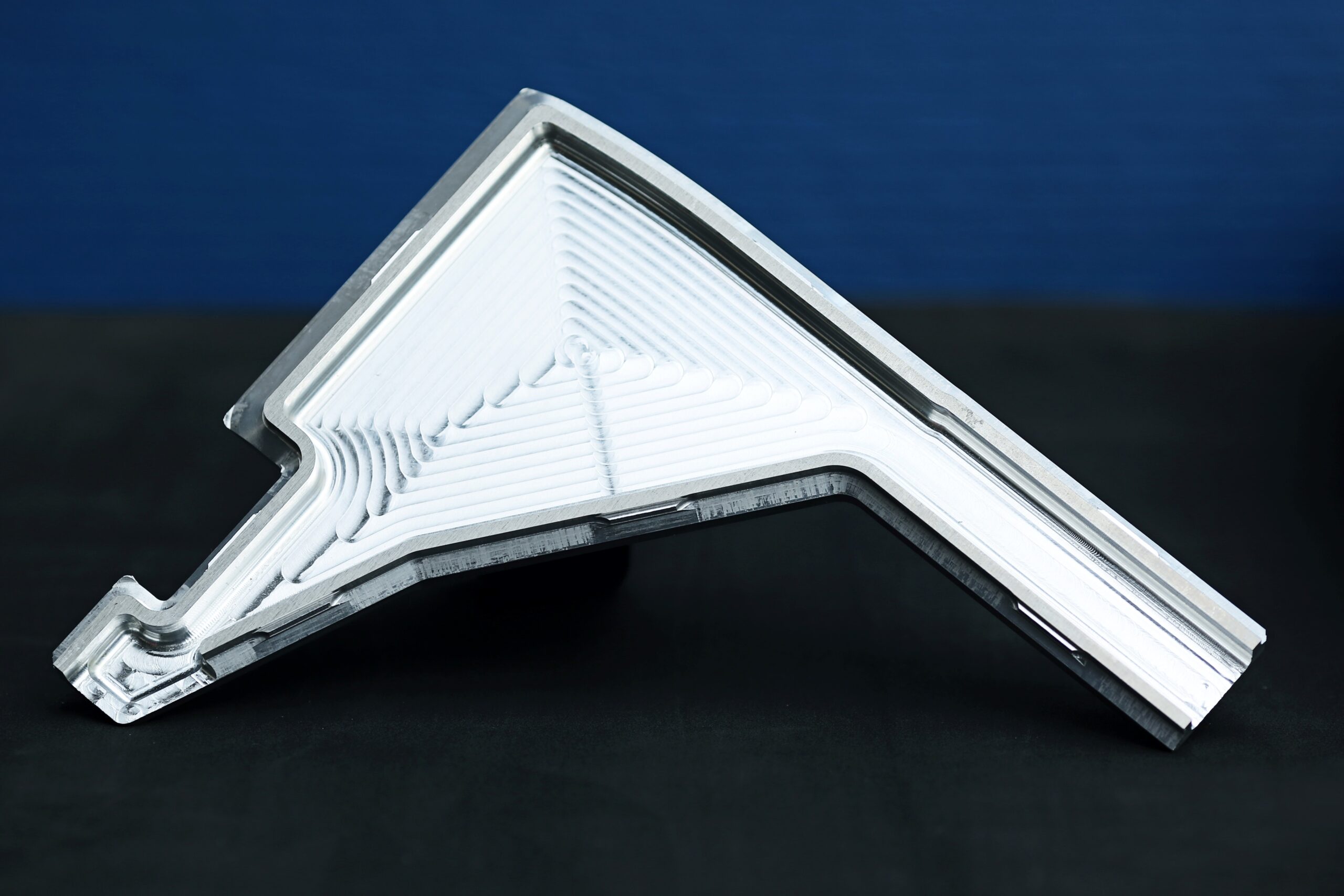

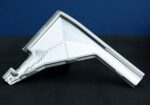

Today we are proud to be able to produce individually designed components for our customers using state-of-the-art technology.

Ingenuity and competence are essential factors in our work, always with the aim of optimizing processes in the best possible way and thus ensuring the highest product quality and customer satisfaction.

Our expertise in metalworking, combined with high flexibility, enables cost-efficient manufacturing, from individual parts to series production.

Our range of services:

• Planning and construction

• Fixture construction

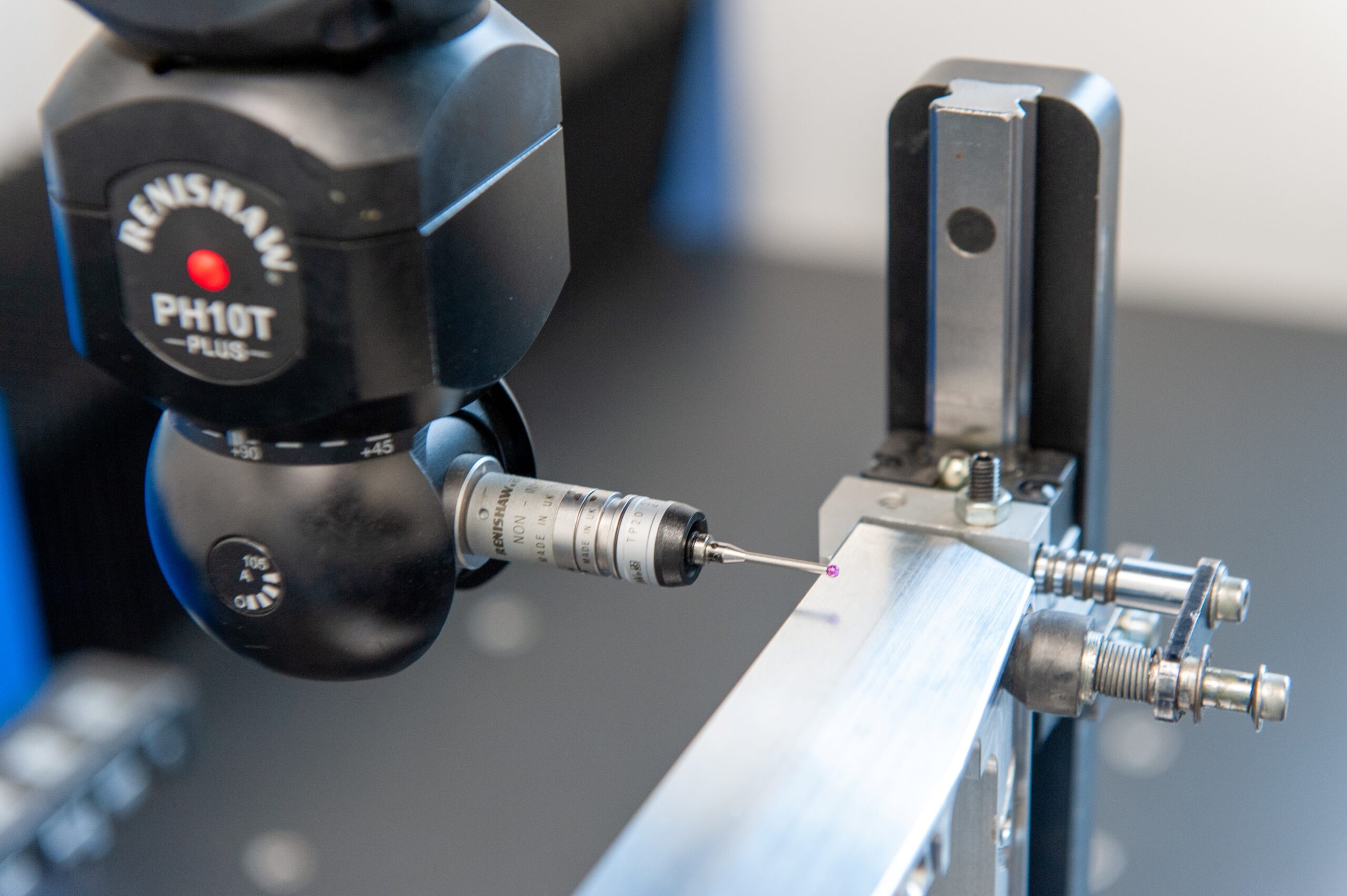

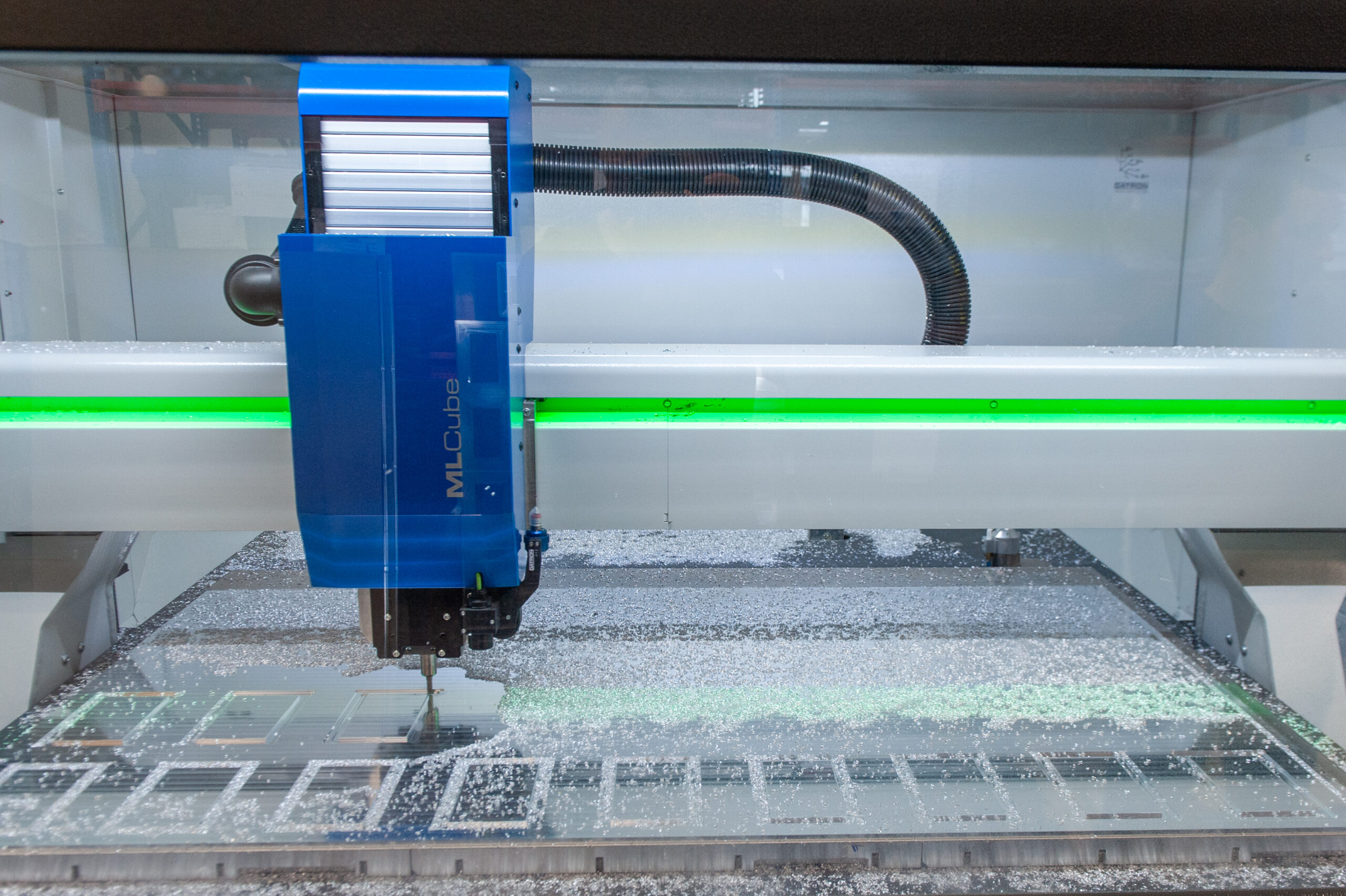

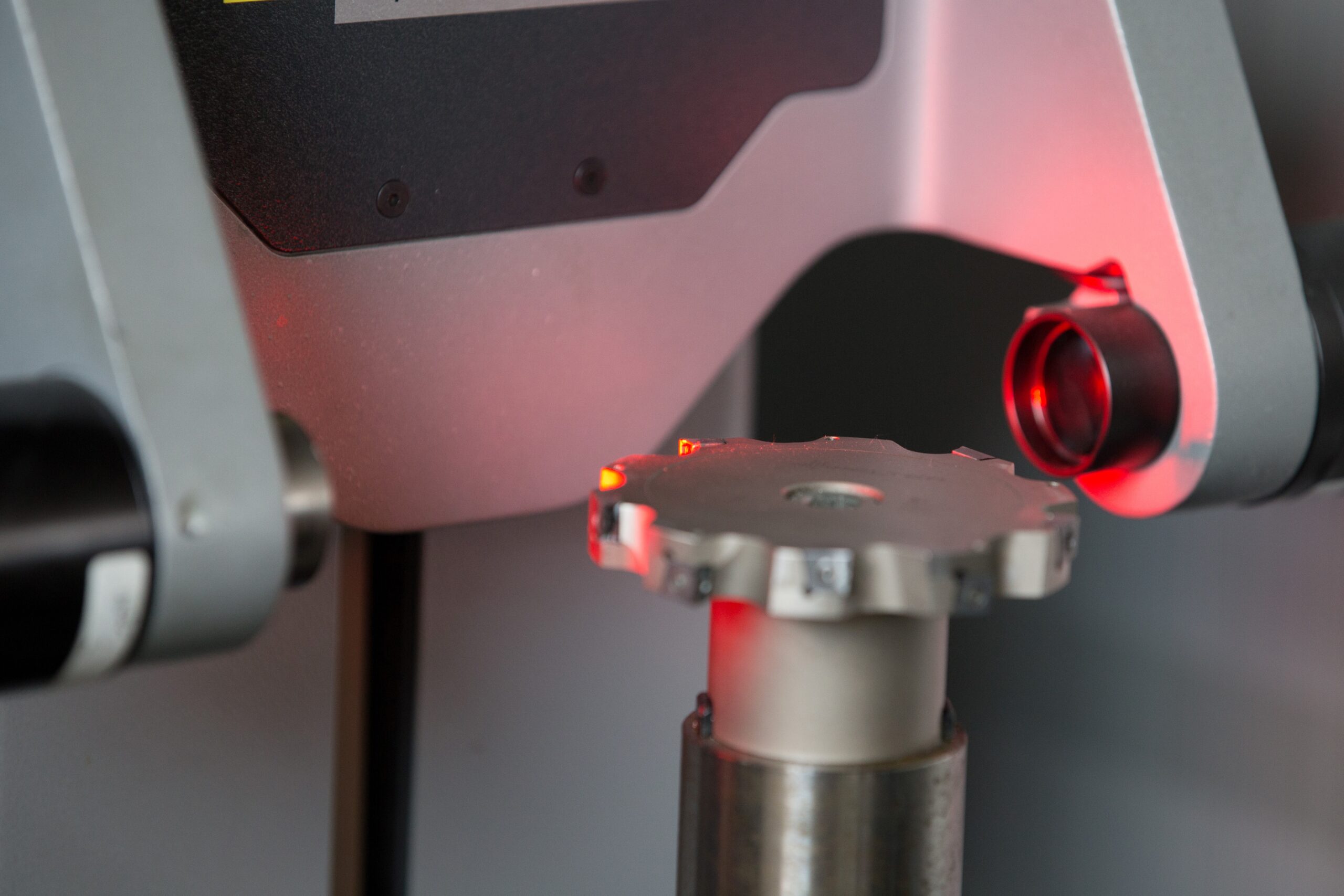

• CNC milling

• CNC turning

• Automated manufacturing – series production

• Finalization and assembly

• Surface treatment in cooperation with long-standing partner companies

Possible workpiece sizes:

• Turning: Max. workpiece diameter – 460 mm; Max. workpiece length – 705 mm

• Milling: Component sizes between 50 and 800 mm

G. Stadler Metallbearbeitungs-GmbH is a family business that can look back on more than 60 years of company history.

Originally founded as a farrier and wagon smithy, the company has constantly evolved and over the years has matured into a state-of-the-art manufacturing site in the fields of machining and steel construction.

The conversion or new construction of the production facility, the acquisition of new technologies and the certification according to ISO 9001:2015 were considered key milestones.

Today we are proud to be able to produce individually designed components for our customers using state-of-the-art technology.

Ingenuity and competence are essential factors in our work, always with the aim of optimizing processes in the best possible way and thus ensuring the highest product quality and customer satisfaction.

Our expertise in metalworking, combined with high flexibility, enables cost-efficient manufacturing, from individual parts to series production.

Our range of services:

• Planning and construction

• Fixture construction

• CNC milling

• CNC turning

• Automated manufacturing – series production

• Finalization and assembly

• Surface treatment in cooperation with long-standing partner companies

Possible workpiece sizes:

• Turning: Max. workpiece diameter – 460 mm; Max. workpiece length – 705 mm

• Milling: Component sizes between 50 and 800 mm

Service areas

TURN,MILLING

Turning workpiece - max. length (mm)

705

Turning workpiece - max. diameter (mm)

460

Milling workpiece - max. length (mm)

800

Milling workpiece - max. width (mm)

800

Milling workpiece - max. height (mm)

500

Upload PDF

Location

Schmalzhofen 1, 5145 Neukirchen an der Enknach, Austria

Listing Information

Sabrina Guric

Offline Now

Please login to view the seller information.

Ask Any Question

Explore Similar Listings

DISTech Disruptive Technologies GmbH

New

Service areas

TURN,MILLING,SURFACE GRINDING,WIRE EDM,START HOLE EDM,MEASURE,ADDITIVE MANUFACTURING TECHNOLOGIES,PROGRAM

- Austria

- 2 days ago

- 15 views

Gerhard Rauch GmbH

Service areas

TURN,MILLING,SURFACE GRINDING,CYLINDRICAL GRINDING,SAWS,WIRE EDM,DIE SINK EDM,LABEL,MEASURE

- Austria

- 2 months ago

- 194 views

DNS Manufacturing Technology GmbH

Service areas

TURN,MILLING,LABEL,MEASURE,PROGRAM

- Austria

- 3 months ago

- 216 views