Basic machine:

Universal milling machine DMU 200 P

(new Y-KGT and new Y scale installed)

Main drive:

Motor spindle 10,000 rpm / 44 kW (40% ED); 32 kW (100% ED) / 2nd spindle installed (currently approx. 15,000 hours)

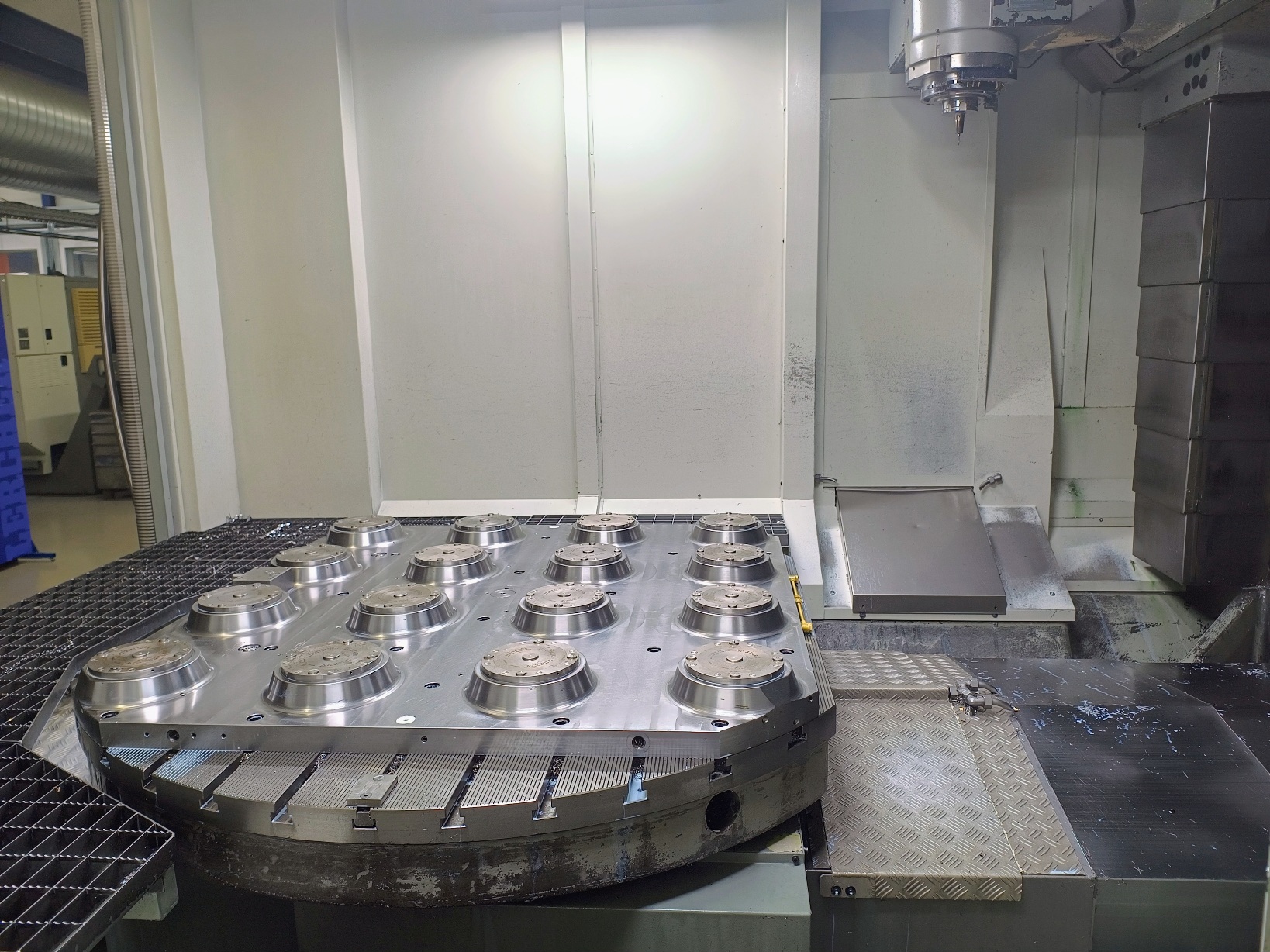

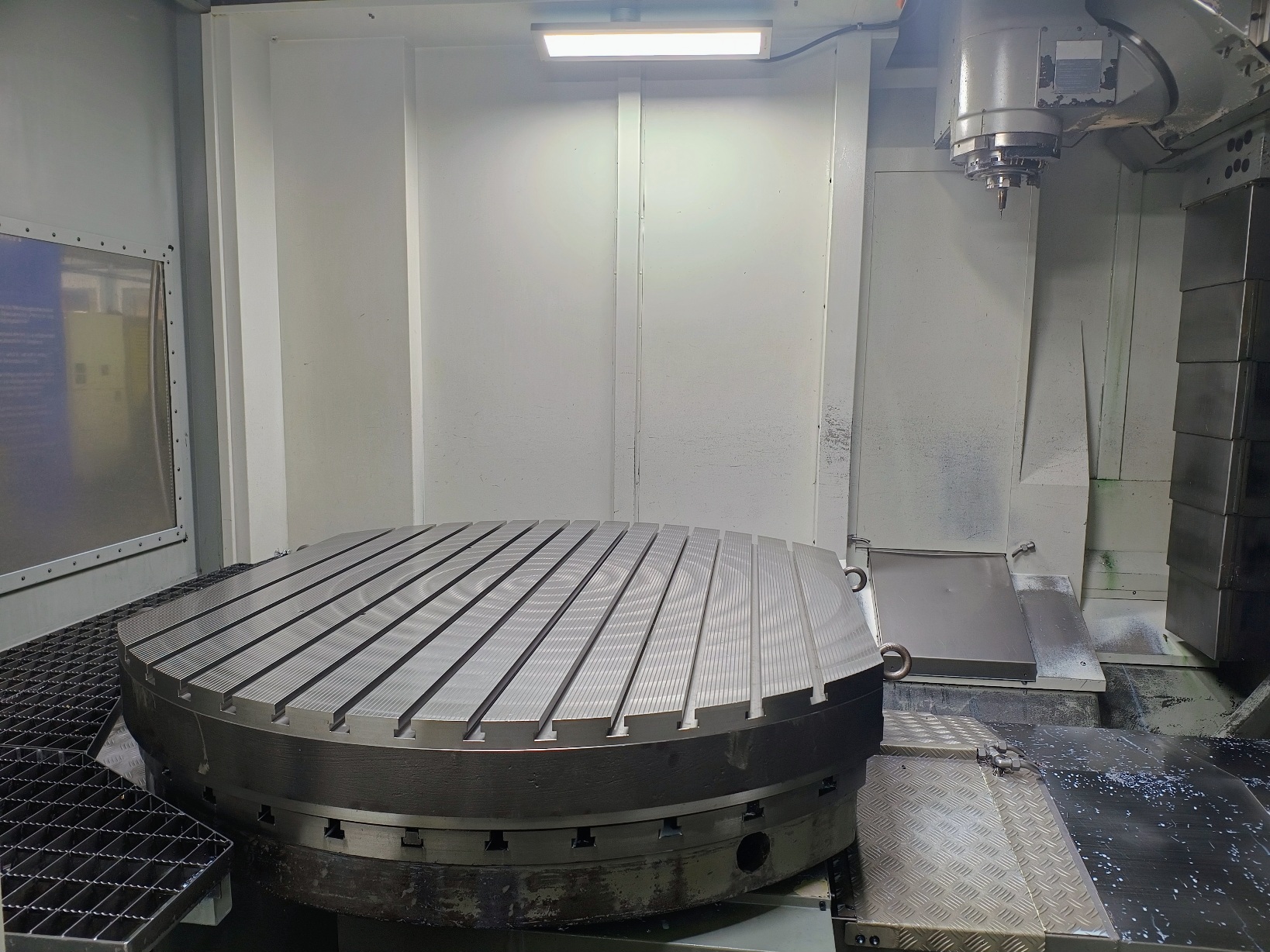

NC rotary table: 1,700 mm x 1,400 mm

Hydraulic clamping system for NC rotary table including 16-fold Stark clamping system and T-slot table mountable

Vertical tool changing device with double gripper, 100 magazine positions HSK-A100

Chip conveyor

rotating viewing window

Electronic handwheel

Heidenhain TS 641 infrared measuring probe

Steering:

3D path control iTNC 530

Milling head:

Universal milling head with controlled

B-axis

Cooling media:

• Oil and emulsion mist separation system

• Electrostatic filter

• Cooling device: blown air through spindle center, selectable via M-function

• Cleaning gun with pump

• 1 bar/40 l/min (theoretical pump capacity)

• Coolant temperature control, heating and cooling, 2 pressure stages

• Coolant system 900 l with paper band filter, 40 bar/23 l/min, 80 bar/15 l/min (theoretical pump capacity) selectable via M function

Location

Listing Information

Rudolf Fluch

Please login to view the seller information.

Ask Any Question

Explore Similar Listings

AXA traveling column machining center for pendulum machining

- Austria

- 4 days ago

- 37 views

DMG MORI DMU 65 Monoblock with RS20 pallet changer

- Germany

- 2 weeks ago

- 119 views

AGIE die-sinking EDM machine AGIETRON ADVANCE 3

- Austria

- 2 weeks ago

- 114 views